Engineers at LLNL are developing revolutionary desalination technologies that use electricity to remove salt from water using a process called capacitive deionization (CDI).

Using electricity as an efficient desalination technique

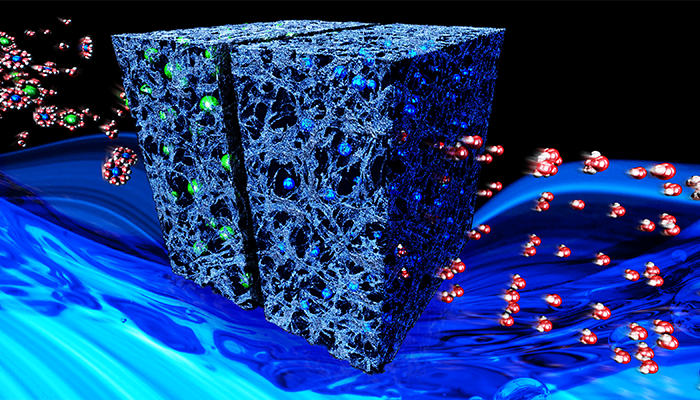

CDI removes salt from water using an applied voltage to reversibly adsorb and desorb ions from the surface of a capacitor. After charging the cell, desalinated water inside the capacitor can be swept out for collection. During discharging, a portion of the capacitive energy can be harvested and used to power further desalination.

CDI is fundamentally more energy efficient for treating low salinity brackish water than traditional desalination technologies because it operates at low pressure and can reuse energy stored during the desalination process.

CDI performs efficiently even at small scale, and is ideally suited to treat water in remote locations.

Pioneering a flow-through electrode design for CDI

The CDI devices under development at LLNL are made from carefully engineered hierarchical carbon aerogel monoliths (HCAMs). These materials have good electrical conductivity due to their monolithic nature, ample micrometer-sized macropores for allowing water to flow freely through the electrode itself, and high internal surface area due to numerous sub-nanometer pores created by the activation process. The flow-through electrode (FTE) design pioneered by LLNL has the advantage of maintaining high charge efficiency (ions removed/electrical current) without the use of expensive membranes.

Operating a CDI device to achieve optimal throughput and energy efficiency for a given desired separation is non-trivial. At LLNL, we work extensively on understanding how operation-mode physics impacts device performance and long-term stability. We have recently pioneered concepts ranging from understanding CDI cycling charge efficiency to how to properly define relevant performance metrics.

Selective ion removal

Another major application of CDI is for selective ion removal. We are developing operation modes and engineered carbon materials for the purpose of selectively removing nitrate and hardness (calcium, magnesium). By tuning our material pore structure, we have demonstrated exceptional intrinsic selectivities for nitrate over common interferent ions like chloride and sulfate.

For information about licensing LLNL CDI technology, please contact Annemarie Meike (meike1 [at] llnl.gov (meike1[at]llnl[dot]gov)).

Publications

M. Cerón, F. Aydin, S. Hawks, D. Oyarzun, C. Loeb, A. Deinhart, C. Zhan, T.A. Pham, M. Stadermann, P. Campbell, Cation Selectivity in Capacitive Deionization: Elucidating the Role of Pore Size, Electrode Potential and Ion Dehydration, ACS Applied Materials & Interfaces 12, 42644 (2020).

D.I. Oyarzun, S. Hawks, P.G. Campbell, A. Hemmatifar, A. Krishna, M. Stadermann, J.G. Santiago, Energy transfer for storage or recovery in capacitive deionization using a DC-DC converter, J. Power Sources 448, 227409 (2020).

F. Aydin, M.R. Cerón, S.A. Hawks, D.I. Oyarzun, C. Zhan, T.A. Pham, M. Stadermann, P.G. Campbell, Selectivity of Nitrate and Chloride Ions in Microporous Carbons: The Role of Anisotropic Hydration and Applied Potentials, Nanoscale 12, 20292 (2020).

H.A. Kuo, A. Ramachandran, D.I. Oyarzun, E.C. Clevenger, J.G. Santiago, M. Stadermann, P.G. Campbell, S.A. Hawks, Understanding resistances in capacitive deionization devices, Environ. Sci.: Water Res. Technol. 6, 1842 (2020).

A. Ramachandran, D.I. Oyarzun, S.A. Hawks, P.G. Campbell, M. Stadermann, J.G. Santiago, Comments on “Comparison of Energy Consumption in Desalination by Capacitive Deionization and Reverse Osmosis”, Desalination 461, 30 (2019).

A. Ramachandran, D.I. Oyarzun, S.A. Hawks, M. Stadermann, J.G. Santiago, High Water Recovery and Improved Thermodynamic Efficiency for Capacitive Deionization Using Variable Flowrate Operation, Water Research 155, 76 (2019).

S.A. Hawks, A. Ramachandran, P.G. Campbell, M.E. Suss, P.M. Biesheuvel, J.G. Santiago, M. Stadermann, Performance Metrics for the Objective Assessment of Capacitive Deionization Systems, Water Res. 152, 126 (2019).

C. Zhan, M.R. Cerón, S.A. Hawks, M. Otani, B.C. Wood, T.A. Pham, M. Stadermann, P.G. Campbell, Specific ion effects at graphitic interfaces, Nature Communications 10, 4858 (2019).

S. Hawks, M. Ceron, T.A. Pham, C. Zhan, C. Loeb, D. Mew, A. Deinhart, B. Wood, J. Santiago, M. Stadermann, P. Campbell, Using Ultramicroporous Carbon for the Selective Removal of Nitrate with Capacitive Deionization, Environ. Sci. Technol. 53, 10863 (2019). Featured on cover: September 2019

D.I. Oyarzun, A. Hemmatifar, J.W. Palko, M. Stadermann, J.G. Santiago, Adsorption and Capacitive Regeneration of Nitrate Using Inverted Capacitive Deionization with Surfactant Functionalized Carbon Electrodes, Sep. Purif. Technol. 194, 410 (2018).

Y. Qu, P.G. Campbell, A. Hemmatifar, J.M. Knipe, C.K. Loeb, J.J. Reidy, M.A. Hubert, M. Stadermann, J.G. Santiago, Charging and Transport Dynamics of a Flow-Through Electrode Capacitive Deionization System, J. Phys. Chem. B 122, 240 (2018).

A. Ramachandran, S.A. Hawks, M. Stadermann, J.G. Santiago, Frequency Analysis and Resonant Operation for Efficient Capacitive Deionization, Water Res. 144, 581 (2018).

D.I. Oyarzun, A. Hemmatifar, J.W. Palko, M. Stadermann, J.G. Santiago, Ion Selectivity in Capacitive Deionization with Functionalized Electrode: Theory and Experimental Validation, Water Res. X 209, 100008 (2018).

S.A. Hawks, J.M. Knipe, P.G. Campbell, C.K. Loeb, M.A. Hubert, J.G. Santiago, M. Stadermann, Quantifying the Flow Efficiency in Constant-Current Capacitive Deionization, Water Res. 129, 327 (2018).

A. Ramachandran, A. Hemmatifar, S.A. Hawks, M. Stadermann, J.G. Santiago, Self Similarities in Desalination Dynamics and Performance Using Capacitive Deionization, Water Res. 140, 323 (2018).

D.I. Oyarzun, A. Hemmatifar, J.W. Palko, M. Stadermann, J.G. Santiago, Adsorption and Capacitive Regeneration of Nitrate Using Inverted Capacitive Deionization with Surfactant Functionalized Carbon Electrodes, Sep. Purif. Technol. 194, 410 (2018).

Y. Qu, P.G. Campbell, A. Hemmatifar, J.M. Knipe, C.K. Loeb, J.J. Reidy, M.A. Hubert, M. Stadermann, J.G. Santiago, Charging and Transport Dynamics of a Flow-Through Electrode Capacitive Deionization System, J. Phys. Chem. B 122, 240 (2018).

A. Ramachandran, S.A. Hawks, M. Stadermann, J.G. Santiago, Frequency Analysis and Resonant Operation for Efficient Capacitive Deionization, Water Res. 144, 581 (2018).

D.I. Oyarzun, A. Hemmatifar, J.W. Palko, M. Stadermann, J.G. Santiago, Ion Selectivity in Capacitive Deionization with Functionalized Electrode: Theory and Experimental Validation, Water Res. X 209, 100008 (2018).

S.A. Hawks, J.M. Knipe, P.G. Campbell, C.K. Loeb, M.A. Hubert, J.G. Santiago, M. Stadermann, Quantifying the Flow Efficiency in Constant-Current Capacitive Deionization, Water Res. 129, 327 (2018).

A. Ramachandran, A. Hemmatifar, S.A. Hawks, M. Stadermann, J.G. Santiago, Self Similarities in Desalination Dynamics and Performance Using Capacitive Deionization, Water Res. 140, 323 (2018).

A. Hemmatifar, J.W. Palko, M. Stadermann, J.G. Santiago, Energy Breakdown in Capacitive Deionization, Water Res. 104, 303 (2016).

Y. Qu, P.G. Campbell, L. Gu, J.M. Knipe, E. Dzenitis, J.G. Santiago, M. Stadermann, Energy Consumption Analysis of Constant Voltage and Constant Current Operations in Capacitive Deionization, Desalination 400, 18 (2016).

Y. Qu, T.F. Baumann, J.G. Santiago, M. Stadermann, Characterization of Resistances of a Capacitive Deionization System, Environ. Sci. Technol. 49, 9699 (2015).

A. Hematifar, M. Stadermann, J.G. Santiago, Two-Dimensional Porous Electrode Model for Capacitive Deionization, Journal of Physical Chemistry C 119, 24681 (2015).

M.E. Suss, P.M. Biesheuvel, T.F. Baumann, M. Stadermann, J.G. Santiago, In Situ Spatially and Temporally Resolved Measurements of Salt Concentration between Charging Porous Electrodes for Desalination by Capacitive Deionization, Environ. Sci. Technol. 48, 2008 (2014).

M.E. Suss, T.F. Baumann, M.A. Worsley, K.A. Rose, T.F. Jaramillo, M. Stadermann, J.G. Santiago, Impedance-based study of capacitive porous carbon electrodes with hierarchical and bimodal porosity, Journal of Power Sources 241, 266 (2013).

M.E. Suss, T.F. Baumann, W.L. Bourcier, C.M. Spadaccini, K.A. Rose, J.G. Santiago, M. Stadermann, Capacitive Desalination with Flow-through Electrodes, Energy Environ. Sci. 5, 9511 (2012).

Patents

High temperature oxygen treated carbon aerogels, M. Stadermann et al, US Patent 10,008,338, June 26, 2018.

Phased charging and discharging in capacitive desalination, M. Stadermann et al, US Patent 9,758,392, September 12, 2017.

System and method for using ultramicroporous carbon for the selective removal of nitrate with capacitive deionization, P. Campbell et al, US Patent Application 20200247693, August 6, 2020.

Flow-through electrode capacitive deionization cell, P. Campbell et al, US Patent Application 20190144310, May 16, 2019.

System and method for high efficiency electrochemical desalination, S. Hawks et al, US Patent Application 20190359506, November 28, 2019.

Multiple pulse charge transfer for capacitive deionization of a fluid, M. Stadermann et al, US Patent Application 20180111854, April 26, 2018.

Capacitive deionization charge transfer from one capacitor simultaneously to multiple capacitors, S. Hunter et al, US Patent Application 20180134588, May 17, 2018.

Systems and methods for electrical energy storage, E. Duoss et al, US Patent Application 20170149083, May 25, 2017.

Energy harvesting with flow-through porous electrodes, M. Suss et al, US Patent Application 20150072267, March 12, 2015.

Segmented electrodes for water desalination, M. Suss et al, US Patent Application 20140202880, July 24, 2014.

People

Learn more about fte-CDI

- Summer students shine in desalination research (LLNL news, June 30, 2020)

- Size matters in ion selectivity and energy storage (LLNL news, October 25, 2019)

- Freshening up contaminated water (LLNL news, August 28, 2019)