Materials scientists at LLNL are developing more robust solid-state battery designs.

Addressing challenges in solid-state battery design

Solid-state batteries have a number of intrinsic performance and safety advantages over conventionally processed batteries based on liquid organic or polymer electrolytes. They can also enable new battery architectures, including 3D designs with much higher theoretical capacity. However, proper design of solid-state batteries remains a formidable challenge.

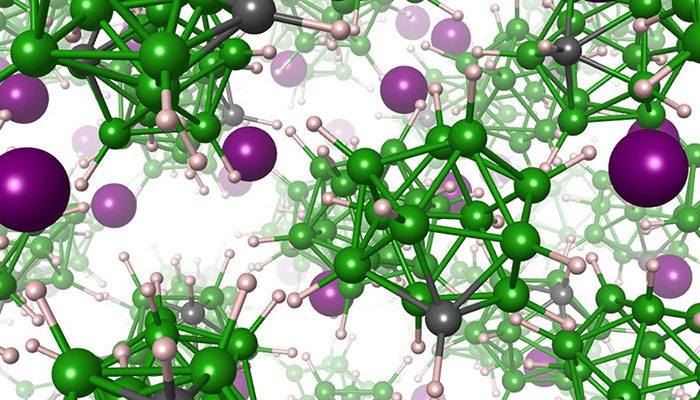

Validated modeling and simulation tools have a unique role to play in the design of both conventional and solid-state batteries, since they can directly probe structure–property relations and provide guidance for optimizing function of component materials. We are developing multiscale, multiphysics modeling frameworks for probing atomistic mechanisms in ion-conducting solid-state electrolytes and assessing microstructural and interfacial impacts on ionic conductivity.

We maintain several software capabilities for simulating ionic conduction and interfacial chemistry in solid-state batteries. To probe atomistic mechanisms and interface effects, we leverage our leadership-class supercomputing facilities to perform large-scale ab initio molecular dynamics. We have also developed a number of unique analysis tools for understanding dynamics in solid electrolytes and devising new descriptors that can be used for materials discovery and optimization.

Beyond the atomic scale

We use our models to predict the effects of microstructure and heterogeneity on ionic conductivity in electrolyte and electrode materials. These models can account for grain boundaries and interfaces in polycrystalline and amorphous materials in order to diagnose potential effects on performance. Our modelers work closely with synthesis teams at LLNL and in industry, applying models to identify key limitations and optimize processing of heterogeneous composite materials for 3D solid-state battery architectures.

The research is sponsored by the Vehicle Technologies Office within the Department of Energy’s (DOE’s) Office of Energy Efficiency and Renewable Energy as well as the DOE High Performance Computing for Energy (HPC4Energy) Innovation program, the Laboratory Directed Research and Development program, and direct support from industrial sponsors.

A. Zevgolis, B.C. Wood, Z. Mehmedović, A. Hall, T. Alves, N. Adelstein, Alloying effects on superionic conductivity in lithium indium halides for all-solid-state batteries, APL Mater. 6, 047903 (2018).

J. Ye, P. Shea, A. Baumgaertel, S. Bonev, M. Biener, M. Bagge-Hansen, Y.M. Wang, J. Biener, B.C. Wood, Amorphization as a pathway to fast charging kinetics in atomic layer deposition-derived titania films for lithium ion batteries, Chem. Mater. 30, 8871 (2018).

M. Dmitrievska, P. Shea, K.E. Kweon, M. Bercx, J.B. Varley, W.S. Tang, A.V. Skripov, V. Stavila, T.J. Udovic, and B.C. Wood, Carbon incorporation and anion dynamics as synergistic drivers of ultrafast diffusion in superionic LiCB11H12 and NaCB11H12, Adv. Energy Mater. 8, 1703422 (2018).

K.E. Kweon, J.B. Varley, P. Shea, N. Adelstein, P. Mehta, T.W. Heo, T.J. Udovic, V. Stavila, B.C. Wood, Structural, chemical, and dynamical frustration: Origins of superionic conductivity in closo-borate solid electrolytes, Chem. Mater. 29, 9142 (2017).

J. Varley, K. Kweon, P. Mehta, P. Shea, T.W. Heo, T. Udovic, V. Stavila, B.C. Wood, Understanding ionic conductivity trends in polyborane solid electrolytes from ab initio molecular dynamics, ACS Energy Lett. 2, 250 (2017).

T.W. Heo, M. Tang, L.-Q. Chen, B.C. Wood, Defects, entropy, and the stabilization of alternative phase boundaries in battery electrode particles, Adv. Energy Mater. 6, 1501759 (2016).

N. Adelstein, B.C. Wood, Role of dynamically frustrated bond disorder in a Li+ superionic solid electrolyte, Chem. Mater. 28, 7218 (2016).

J. Ye, S. Charnvanichborikarn, M.A. Worsley, S.O. Kucheyev, B.C. Wood, Y.M. Wang, Enhanced electrochemical performance of ion-beam-treated 3D graphene aerogels for lithium ion batteries, Carbon 85, 269 (2015).

T.W. Heo, L.-Q. Chen, B.C. Wood, Phase-field modeling of diffusional phase behaviors of solid surfaces: A case study of phase-separating LiXFePO4 electrode particles, Comp. Mater. Sci. 108, 323 (2015).

J. Ye, M.T. Ong, T.W. Heo, P.G. Campbell, M.A. Worsley, Y. Liu, S.J. Shin, S. Charnvanichborikarn, M.J. Matthews, M. Bagge-Hansen, J.R.I. Lee, B.C. Wood, Y.M. Wang, Universal roles of hydrogen in electrochemical performance of graphene: High rate capacity and atomistic origins, Sci. Rep. 5, 16190 (2015).

Y. Liu, Y.M. Wang, B.I. Yakobson, B.C. Wood, Assessing carbon-based anodes for lithium-ion batteries: A universal description of charge-transfer binding, Phys. Rev. Lett. 113, 028304 (2014).

People

Learn more about solid-state batteries

- Scientists find ‘frustration’ in battery materials (LLNL news, February 22, 2018)

- Getting more life out of lithium-ion batteries (LLNL news, July 23, 2014)