Engineers at LLNL developed a flexible dual-phase membrane technology for applications such as carbon capture, fuel cells, and ammonia production.

Dual-phase membranes address challenges in energy technology

Membranes are critical for various energy related technologies. However, for emerging applications, increasing the mechanical performance, operating temperature range, chemical stability, and selectivity of membranes remains challenging. Typical polymer membranes cannot operate at high temperatures (above 150°C) and degrade in extreme chemical environments (such as alkaline).

To address these challenges, LLNL researchers developed a dual-phase membrane technology that employs a liquid phase maintained by capillary force in a porous solid phase. This method enables remarkable control over membrane properties by making simple adjustments to the liquid phase chemistry and/or solid support morphology, and thus can be tailored to suit a variety of applications and operating temperatures.

Novel membranes for various applications

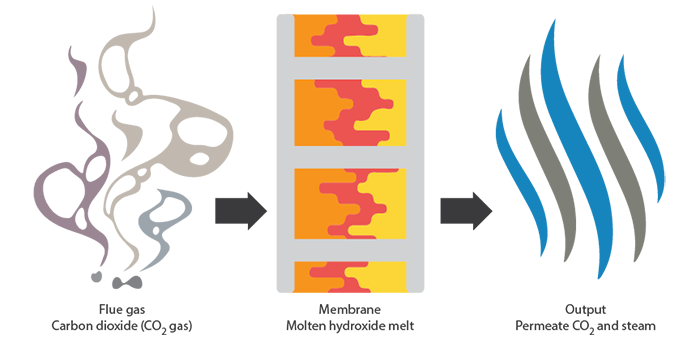

A gas separation membrane containing the optimized molten hydroxide solution held in a porous material selectively turns CO2 into carbonates, which are transported across the membrane by diffusion. Water—as steam—on the sweep (right) side is critical for recovering the captured carbon for storage by converting the carbonate back into CO2.

A novel application of this technology—called hydroxide/ceramic dual-phase (HCDP) membranes—utilizes molten hydroxide mixtures as the ion-conducting transport phase supported by a porous ceramic material. The optimized hydroxide mixture reacts with carbon dioxide (CO2) to form carbonates in a process that captures carbon efficiently and cost effectively. Our researchers demonstrated that this technology outperforms polymer and molten carbonate membranes when separating CO2 from fossil fuel powerplant flue gas.

The technology has wide applications beyond large-scale carbon capture and sequestration. HCDP membranes, when coupled with electrocatalysts, can also provide excellent performance in intermediate temperature anion-exchange membrane fuel cells. Future adjustments can combine alternative liquid phases and porous support to enable a variety of applications ranging from ammonia production, oxygen separation, and carbon dioxide reduction.

Since the method is compatible with additive manufacturing (AM) techniques such as projection microstereolithography (PµSL) and direct-ink writing (DIW), it enables rapid prototyping of optimized membrane designs and provides a new AM “feedstock” to expand the applicability of AM into other fields of research.

Publications

M.R. Cerón, L.S. Lai, A. Amiri, M. Monte, S. Katta, J.C. Kelly, M.A. Worsley, M.D. Merrill, S. Kim, P.G. Campbell, Surpassing the conventional limitations of CO2 separation membranes with hydroxide/ceramic dual-phase membranes, Journal of Membrane Science 567, 191 (2018).

Patent Applications

Porous ceramic structure for carbon dioxide capture, P. Campbell, US Patent Application 20190389778, December 26, 2019.

Molten hydroxide membrane for separation of acid gases from emissions, M. Worsley, US Patent Application 20170333834, November 23, 2017.

People

Learn more about these membranes

- A Reversible Reaction Captures Carbon (Science & Technology Review, December 2017)